Noise control in ventilation

Why is it such an issue? In 1999 the WHO (World Health Organisation)…

Type R / A & B / C

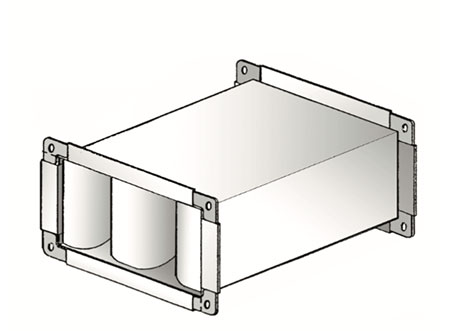

The well established range of TEK rectangular attenuators is designed to give the building services industry a practical product for all situations. They have all been researched and designed by a leading independent acoustic consultant and tested to BS 4718 1971.

All TEK products are designed in-house by engineers with many years’ experience. This means that we are not restricted to standard sizes and attenuators can be tailor-made to meet your requirements. Our acoustic design service is available to ensure that you receive the best possible advice at the planning stage, thereby avoiding site problems later on.

Casing & Splitters:

The notation for a standard rectangular attenuator is type RCP. The prefix R and suffix P are as indicated below. the second letter C indicates a standard splitter.

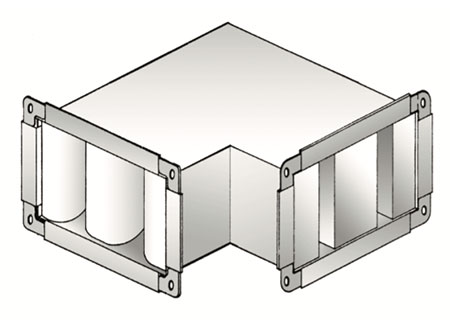

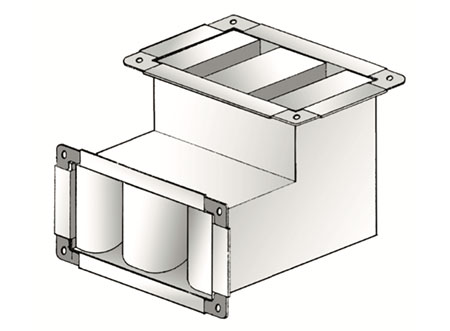

Prefix A: Bend attenuators are available, supplied with short cord turning vanes installed in the airways (having horizontal splitters).

Prefix B: As Prefix A with vertical splitters.

Suffix P: Splitter acoustic infill retained behind perforated sheet steel.

Suffix L: Attenuators may be supplied with low loss fairing on the splitter end to lower pressure drop across the attenuator. Acoustic performance of the attenuator will be degraded.

Casing & Splitters:

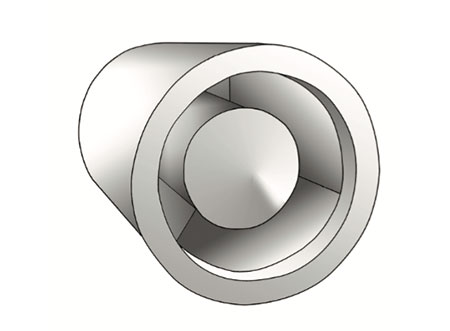

Prefix C: Standard circular attenuator.

Prefix P: Pod installed in circular attenuator.

Prefix D: This is preceded by a number (normally 1 or 2) indicating the length of a circular attenuator as a multiple of the attenuator internal diameter.

The infill is inorganic mineral wool or glass fibre rigid slabs with a glass fibre tissue face to limit fibre erosion. The fibre is inert, vermin, rot, and moisture proof, non-combustible and does not support bacteriological growth, packed to a density of not less than 45 kg/m3. The infill has been tested for fire and has a Class spread of flame (as measured to BS476: Part 7: 1971).

Attenuators may be supplied in sections for site assembly by others as required, or as advised by Tek. Nuts, bolts and washers to be supplied by others.

The attenuators have been tested in accordance with BS4718 1971 by an independent consultant. The test procedure eliminates effects due to end reflection, directivity, flanking transmission, standing waves and test chamber sound absorption.

The attenuators have been tested in accordance with BS4718 1971 by an independent consultant.

Where our standard specification does not cover the installation requirements, select the extra features required from the list below. Simply add the suffix to the standard attenuator code e.g. RCPSAT = attenuator for use in saturated atmosphere.

Suffix M: Polyester membrane installed under the perforated metal typically for protection from grease, moisture or oil-laden atmosphere.

Suffix C: Polyester membrane suitable for operating and clean rooms enclosing acoustic infill hermetically, using polyester strip sealant. Acoustic infill retained behind perforated steel sheet or expanded metal hot dipped galvanised after perforation. Attenuators thoroughly cleaned prior to despatch and fitted with sealed end plates.

Suffix PVF: PVF2 anti-corrosion paint may be applied to all internal metal surfaces to offer resistance to corrosive air.

Suffix SAT: Perforated sheet metal or expanded metal retaining the acoustic infill may be supplied hot dipped galvanised after perforation for use in saturated atmosphere. The infill would be encased with a polyester membrane.

Suffix H: High pressure attenuators may be provided constructed in accordance with the recommendations of the HVCA for the construction of rectangular ducts in high velocity air systems.

Suffix S: Crosstalk attenuators may be supplied with spigot connections in lieu of flanges. Attenuator configuration may be selected to customers’ requirements.

Suffix PVC: Plastic attenuators may be supplied for installation in a highly corrosive atmosphere. Attenuator casings and perforated sheet would be manufactured from PVC.

Attenuator Weights / Rectangular – Type RCP

| Width mm | Height mm | Length mm | ||||||

| 600 | 900 | 1200 | 1500 | 1800 | 2100 | 2400 | ||

| 300 | 300 | 21 | 27 | 36 | 42 | 49 | 56 | 63 |

| 300 | 600 | 34 | 42 | 55 | 65 | 75 | 88 | 98 |

| 600 | 600 | 50 | 66 | 87 | 703 | 118 | 134 | 150 |

| 600 | 900 | 60 | 87 | 113 | 134 | 155 | 176 | 197 |

| 600 | 1200 | 86 | 114 | 140 | 165 | 191 | 217 | 243 |

| 600 | 1500 | 105 | 135 | 166 | 196 | 226 | 256 | 286 |

| 900 | 600 | 69 | 91 | 119 | 141 | 163 | 185 | 207 |

| 900 | 900 | 88 | 116 | 152 | 180 | 208 | 236 | 264 |

| 900 | 1200 | 116 | 151 | 185 | 220 | 255 | 290 | 325 |

| 900 | 1500 | 137 | 178 | 219 | 259 | 300 | 341 | 382 |

| 900 | 1800 | 158 | 205 | 252 | 299 | 346 | 393 | 440 |

| 1200 | 600 | 94 | 122 | 150 | 178 | 207 | 236 | 265 |

| 1200 | 900 | 119 | 155 | 191 | 226 | 262 | 298 | 334 |

| 1200 | 1200 | 144 | 188 | 232 | 275 | 319 | 362 | 405 |

| 1200 | 1500 | 170 | 221 | 272 | 323 | 375 | 426 | 477 |

| 1200 | 1800 | 195 | 254 | 313 | 372 | 431 | 490 | 549 |

| 1500 | 900 | 143 | 186 | 229 | 273 | 316 | 361 | 406 |

| 1500 | 1200 | 172 | 223 | 278 | 330 | 383 | 436 | 488 |

| 1500 | 1500 | 202 | 263 | 325 | 387 | 449 | 511 | 573 |

| 1500 | 1800 | 231 | 302 | 377 | 443 | 518 | 593 | 754 |

| 1800 | 900 | 166 | 217 | 268 | 319 | 370 | 423 | 476 |

| 1800 | 1200 | 200 | 261 | 322 | 384 | 446 | 508 | 570 |

| 1800 | 1500 | 234 | 306 | 378 | 450 | 523 | 596 | 756 |

| 1800 | 1800 | 268 | 350 | 433 | 516 | 600 | 783 | 866 |

| 1800 | 2100 | 301 | 395 | 488 | 582 | 790 | 883 | 976 |

| 1800 | 2400 | 335 | 439 | 543 | 774 | 878 | 982 | 1086 |

| 2100 | 1800 | 304 | 399 | 494 | 589 | 798 | 893 | 988 |

| 2100 | 2100 | 342 | 449 | 556 | 791 | 898 | 1005 | 1112 |

| 2100 | 2400 | 380 | 498 | 618 | 878 | 996 | 1116 | 1236 |

| 2400 | 2400 | 425 | 558 | 850 | 983 | 1116 | 1408 | 1541 |

Why is it such an issue? In 1999 the WHO (World Health Organisation)…

TEK Focus 2020 Wow 2020 already; not only a new year but a…

Ventilating Residential Apartments Why is there a need? In 2017 the population of the UK was an estimated…